Koryx Copper Provides Project Development Update for the Haib Copper Project, Southern Namibia

Including Pea-Guidance, Met Test Results, Power and Water Studies and Mining Permit Update

Highlights

- Metallurgical testwork program with encouraging preliminary results including 89% average flotation recovery from 120-150µm grind size producing clean concentrate with grade of 20-25% Cu.

- Pre-concentration and heap leach testwork ongoing with encouraging initial results.

- PEA on track to be published during Q3 2025 intended to demonstrate techno-economic feasibility of Haib as a conventional, long-life, low-cost, large-scale open-pit mine with a simple but large milling & flotation (M/F) process base case, producing Cu in clean concentrate, with significant additional Cu cathode production from a heap-leach (H/L) expansion scenario.

- Infill & expansion drilling ongoing with 4 rigs on-site and additional 4 rigs to mobilise Q3 2025. Current 55,000 m program to complete Q1 2026. Aiming to increase size & grade of the deposit, to be reflected in a MRE update and follow-on technical study update during H1 2026 to capture additional project value (improved MRE & flowsheet plus infrastructure optimisation).

- Water and power supply studies indicating approximately 120MW of average power demand for milling and flotation and 20Mm3 pa of required water supply for the M/F base-case.

- Mining license application submission, environmental permitting progressing.

-

Koryx corporate and site infrastructure now includes a total permanent staff complement of >50 (including 12 geologists and 4 engineers), 4 diamond drill rigs plus various earth moving vehicles for road and drill pad prep. In addition, Koryx is working with a range of world-class technical specialists and consultants from especially South Africa, Namibia and Chile.

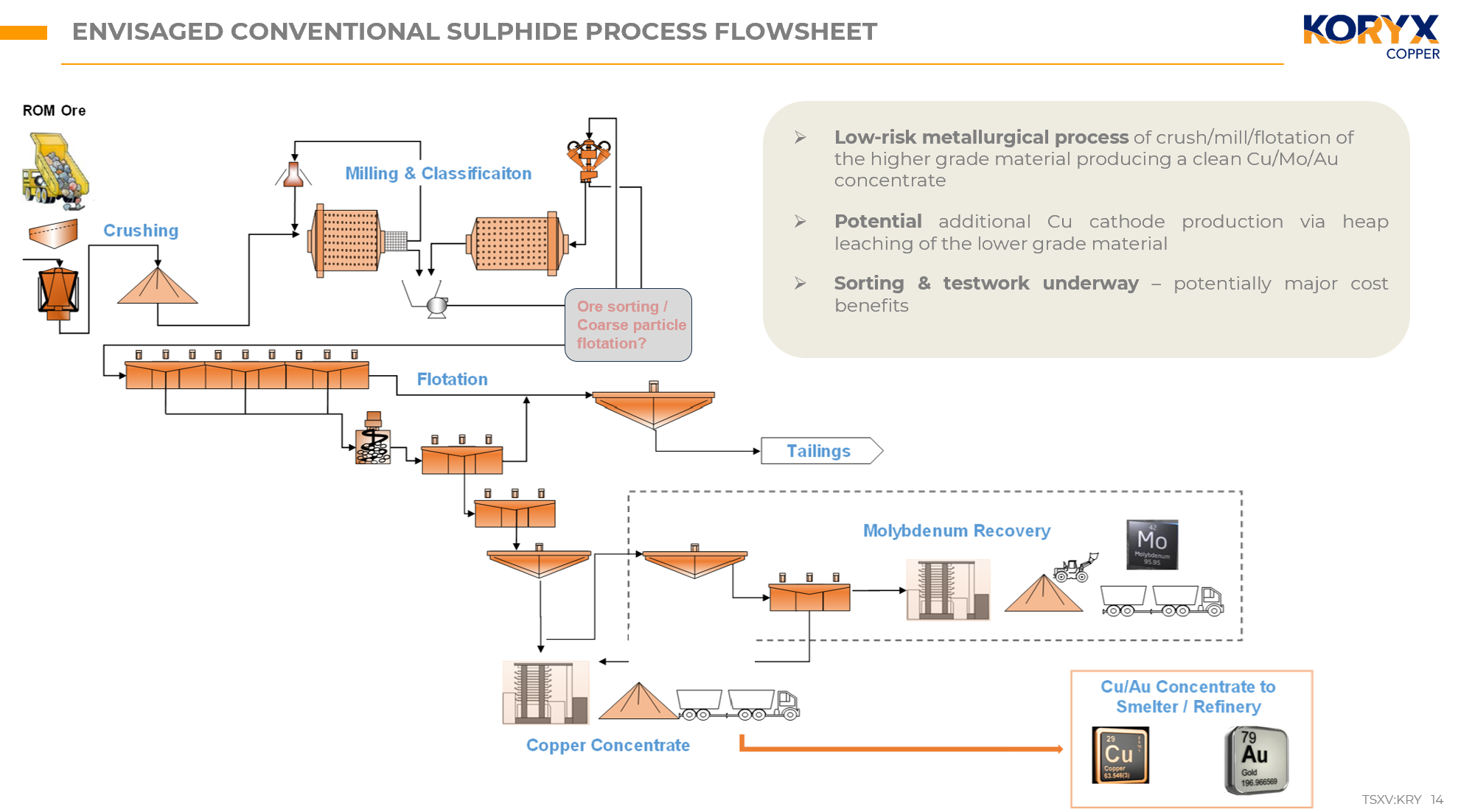

VANCOUVER, British Columbia, June 17, 2025 (GLOBE NEWSWIRE) -- Koryx Copper Inc. (“Koryx” or the "Company") (TSX-V: KRY, NSX: KYX) is pleased to announce significant project progress for its wholly-owned Haib Copper Project (“Haib” or the “Project”) in southern Namibia. Haib is an advanced-stage copper/molybdenum project that is envisaged to produce clean copper concentrate via conventional crushing/milling/flotation, with the potential for additional copper production via heap leaching.

Heye Daun, Koryx Copper’s President and CEO commented: “We are very pleased with the substantial progress we have made with the met testwork, process flowsheet and infrastructure development aspects of the Haib copper project during the last 6 months. Results are highly encouraging and are being incorporated in the preliminary economic assessment (PEA) which we are preparing to publish in Q3 2025.

This high-quality PEA is intended to demonstrate techno-economic feasibility of Haib as a conventional, long-life, low-cost, large-scale open-pit mine with a simple milling & flotation process base case, producing Cu in clean concentrates, with additional Cu cathode to be produced from a heap-leach expansion scenario.

We have multiple world-class engineering consultants in the final stages of completing this study. We are also expediting our drill program to be able to produce an improved mineral resource and to capture additional project value through an enhanced technical study during H1 of 2026.

As we incrementally de-risk and improve the Haib copper project our confidence continues to grow that we will turn this formerly forgotten project into Africa’s next simple, but large and world-class copper mine.”

Metallurgical Testwork Progress

Koryx’s metallurgical test program has made excellent progress since January 2025. The concept of using and enhancing the historical process steps, test parameters and reagent suites that had previously been tested by others (Rio Tinto, Teck, Great Fitzroy Mines) over a 25-year period was demonstrated to be very effective.

Multiple samples of Haib mineralisation from various locations within the mineralised system and with a range of copper, molybdenum and gold content in each sample were tested. Successful historical test parameters were used as the basis for tests on these new samples with enhancements to improve copper recovery or reduce costs. Generally, the metallurgical results received were excellent and matched or exceeded the results of the historical programs completed by Mintek in 1996.

The focus of the testwork program was on investigations of conventional comminution and flotation of higher-grade portions of mineralisation (containing more than 0.275% Cu). All minerals processing tests needed to support a Preliminary Economic Analysis for the project have either been completed or will be completed by July 2025. Supplementary heap leaching testing will only be completed in 2026, but the successful bacterial leach test program in 2020 can be used to support the PEA if necessary.

Koryx has chosen to work with multiple well-known and respected test facilities to carry out its PEA testwork:

- Geolabs in South Africa carried out comminution tests.

- Maelgwyn, SGS, Rados International Technologies, TOMRA and Eriez in South Africa have been appointed to carry out a comprehensive set of mineral sorting, dense medium separation, analytical and mineralogical, milling, coarse particle and conventional flotation tests.

- NextOre in Australia have also evaluated sorting potential of Haib mineralisation.

- Hydrometallurgical leach tests by Mintek in South Africa.

In addition, DRA in South Africa and MJO Ingeniera y Consultores (“MJIO”) in Chile are assisting with coordination of metallurgical tests as well as providing overall process consulting services and oversight to the project.

Milling & Flotation Test Results

- Bond ball work index tests with screening at 106 µm (micrometre) generated Bond Ball Mill Work Index (BBWi) values between 17.5 and 19.4 kWh/t.

- Crusher work index (CWi) tests are currently still in progress, but the average CWi value obtained from historical test work in 1996 was 26.5 kWh/t for the +51 -76 mm size fraction.

- Abrasion index (Ai) tests yielded values between 0.26 and 0.40, suggesting relatively high rates of abrasive wear in crushing and grinding circuit operation.

- SMC tests yielded SAG circuit specific energy estimates of 10 to 14 kWh/t.

- These comminution test results would typically be considered indicative of “hard” or “moderately hard” mineralisation, within the range expected for this style of mineralisation.

- Mineralogical evaluations of multiple mineralised samples concluded that > 95% of copper was present mostly in the form of chalcopyrite (CuFeS2) with limited additional presence of bornite (Cu5FeS4). The ratio of chalcopyrite to pyrite (FeS2) varied between 1:1 and 2:1.

- No other base metal sulphides were observed that could result in contamination either of products of the metallurgical process, or of tailings or leach residue streams, supporting production of a clean concentrate.

- Laboratory scale milling and flotation tests determined that copper flotation recovery exceeding 92% can be achieved following a primary grind to 80% passing either 150 or 120 µm to ensure liberation of chalcopyrite and pyrite from each other and from gangue minerals before flotation.

Figure 1: Process Flow Sheet for the Milling & Flotation base case for the Haib Copper Project

- The flotation procedure and reagent additions initially used for the tests at these grinds were replicated on a series of core samples with copper grades varying between 0.19% and 0.71% Cu.

- Excellent recoveries were achieved based on consistent tailings copper grade of around 0.035%, indicating average overall copper recovery of 89% for material at the average mineral resource grade of 0.35% around a range of 83-95% overall recovery for the lowest to highest grade mineralised samples.

- A rougher flotation regrind step was incorporated in the tests after which it was possible to achieve 20% to 25% Cu in final concentrate from all tests.

- The copper flotation tests also demonstrated that between 45% and 70% of molybdenum can be recovered to copper flotation concentrate. Tests are in progress to recover Mo from the copper concentrate and promising interim results indicate that this should be possible.

Pre-concentration Testwork

Maelgwyn, SGS, Rados International Technologies, TOMRA and Eriez in South Africa have been appointed to carry out a comprehensive set of pre-concentration testwork on samples of both high-grade (>0.275% Cu) and low-grade material (0.175% to 0.275% Cu). The testwork comprises mineral sorting, dense medium separation, analytical and mineralogical, milling, coarse particle and conventional flotation tests.

Preliminary results have been encouraging with final results expected before the end of August 2025.

Additional pre-concentration testwork is currently in progress to confirm the potential value of coarse particle flotation (“CPF”) in the milling circuit. Initial results suggest that it may be possible to reject as much as 15% of mill feed to barren coarse tails for disposal, with a significant reduction in flotation plant size without a material concentrator recovery sacrifice.

Heap Leach Testwork

Column leach tests of high and low-grade samples commenced in June 2025, with the primary objective of demonstrating whether a heap leach process is potentially viable for treatment of lower grade mineralisation that cannot be processed profitably through a conventional milling and flotation circuit.

Bacterial leaching, three different chloride leach processes and a nitrate leach technology are all being tested in these column leach tests. This will be a 6-12month test program, with results by early 2026 expected to be appropriate to support the next level of technical studies.

Trade-off Studies and Specialist Infrastructure Assessments

The following trade-off studies have been completed by Koryx and its main Consultants:

- A technical evaluation of more than thirty mineral dressing and hydrometallurgical processes with potential to recover copper from chalcopyrite mineralisation concluded that only the mineral sorting, dense medium separation, coarse particle and conventional flotation and heap leach processes mentioned above are realistic options for processing of Haib mineralisation.

- Comminution test results were used to simulate performance of alternative crushing and milling circuit configurations. It was concluded that, for Haib, the optimal configuration will be primary gyratory crushing, secondary cone crushing, tertiary crushing using high pressure grinding rolls (HPGRs) and a single stage of ball milling.

- Cash flow schedules were prepared for several different annual processing rates and cross-over copper grades between high- and low-grade processing. These considered annual revenues, capital and operating costs and electrical power, as well as water requirements and the capacity of largest available crusher units. It was concluded that the optimum combination would with a Milling and Flotation Concentrator processing material containing > 0.275% Cu followed by the addition of a Heap Leach/Solvent Extraction/Copper Electrowinning circuit processing material containing between 0.175% and 0.275% Cu. The milling and flotation concentrator will produce copper in concentrate, whilst the heap leach circuit will produce copper cathode.

- Modelling of Coarse Particle Flotation (CPF) in the primary milling circuit as tested during this PEA suggested that it will add value to the project. CPF has therefore been included in the base case flowsheet.

- Following evaluation of completed milling and flotation tests, the primary milling circuit was specified to be able to achieve 80% < 120 µm grind while also being able to operate at 80% < 150 µm. Rougher concentrate will be milled to 80% <25 µm before cleaner flotation.

- A molybdenum flotation circuit has been included in the base case, to recover Mo from copper concentrate. This will be operated in batch mode since it is anticipated that it will be profitable to operate it when pockets of mineralisation above average molybdenum content are being mined.

- Four possible process routes to recover copper metal from flotation concentrate on site were evaluated. It was concluded that although these are technically feasible, none of them would add value to the project. The base case therefore produces copper flotation concentrate to be transported off-site for toll smelting and refining by others, as well as copper metal produced directly from low-grade mineralized material by heap leaching and copper SX/EW.

- A major tailings dewatering trade-off study was completed using multiple specialist consultants. The selected option was thickening of flotation tailings and pumping of the slurry to a conventional tailings storage facility on site.

- Five alternative transport methods and routes for flotation concentrate were considered including Walvis Bay, Lüderitz and Gqeberha (Port Elizabeth) in South Africa. It was concluded that product should be trucked to the nearest port (Lüderitz) for shipping to international smelting facilities.

Mine Bulk Power and Water Supply

Supply of both water and power have been investigated to the mine site considering demand from the current conceptual plant configuration:

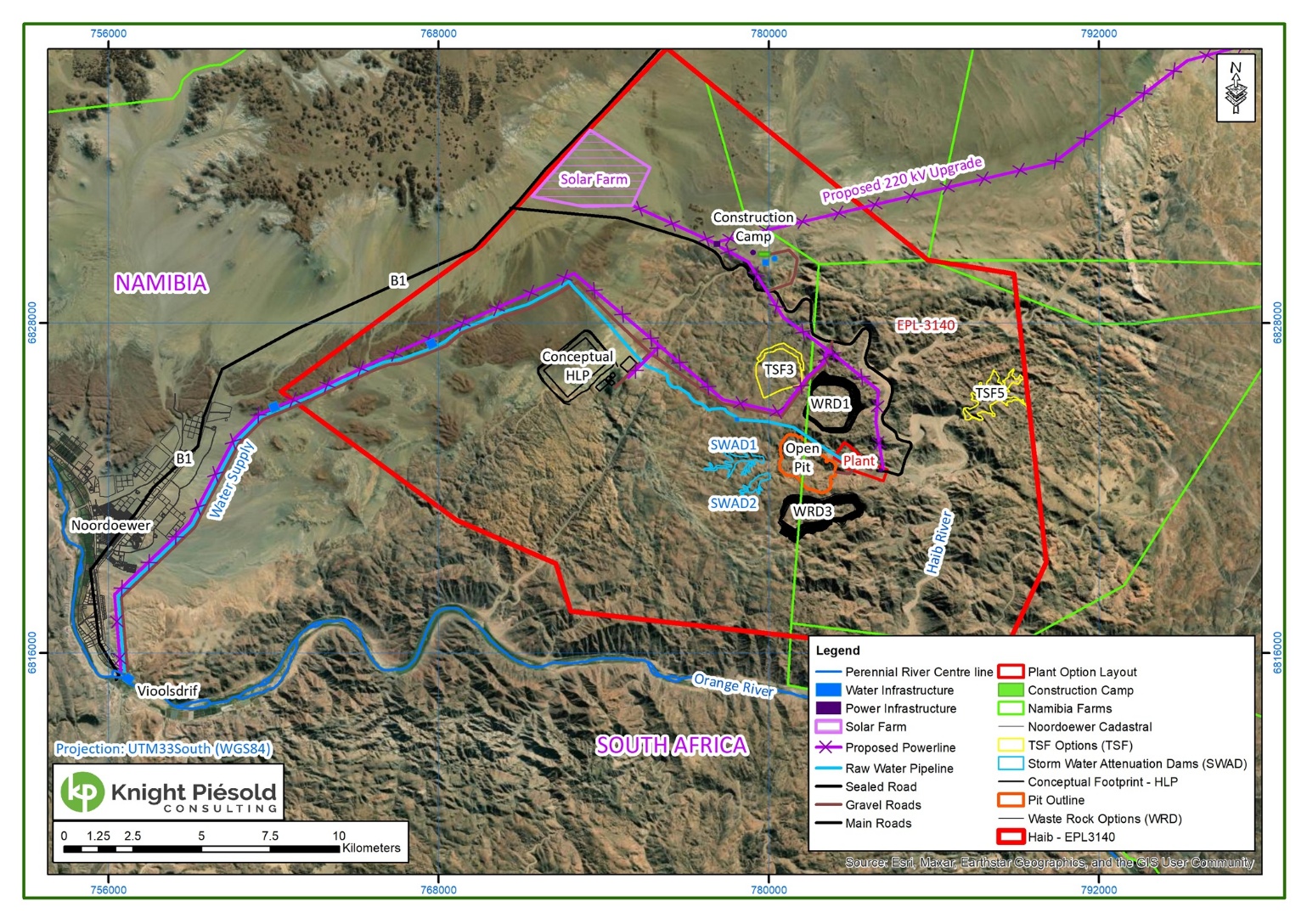

- A power supply concept study evaluated the best options as per the trade-offs to meet the project’s peak demand of 145 MVA (120MVA for M/F and 25MVA for H/L) and annual consumption of 1,123 GWh (mine load plus additional loads). The initial study has identified a hybrid solution combining grid via Harib Substation to the new Haib substation augmented by solar PV as the preferred option.

- The team are currently engaging with the parastatal Namibian power utility, NamPower and have provided the base case project demand to NamPower for their engineers to proceed with a network capacity analysis and confirm what upgrades will be required to the existing grid infrastructure in order to supply the required load.

- A range of possible alternatives for the supply of approximately 20 million m3 per year of raw water have been evaluated on a preliminarily basis. The trade-off studies completed have identified the Orange River (9km away) abstraction and the Neckartal Dam (250km away) as the two most suitable supply alternatives. Either option has advantages and disadvantages from a capex/opex, operability and permitting perspective. Conceptual designs and costings for these two primary options are being produced for further evaluation in collaboration with Namibia’s parastatal bulk water supplier, NamWater.

Mine Site Infrastructure Studies

Detailed specialist studies into non-process plant infrastructure, specifically water, power, roads, concentrate transport tailings deposition are ongoing, with the following results so far:

- The project is easily accessible via the asphalted B1 highway nearby which connects the local town of Noordoewer to Windhoek.

- Up to 60 km of internal access roads have been proposed to connect the accommodation, offices, plant, water and power supply infrastructure, and the tailings storage facility (TSF) area.

- Construction and operational housing requirements were defined at a high level, and a suitable location for a mine camp was identified in the relatively flat western area of the permit.

- Various alternative TSF locations were assessed. The preferred TSF site ad design is a valley impoundment with zoned rockfill embankment and upstream lined face which also makes provision for seepage interception and recycling of water and will accommodate a total of 450mt of thickened flotation tails.

- Storm surface water management for 1:50 year flood events were modelled and mitigation measures to protect infrastructure from flooding have been included in the preliminary design.

- The team has assessed areas proximal to the pit to ensure that there is availability of space for dumping of 775mt of waste rock within a short distance of the pit access ramps.

Site Environmental and Permitting

A comprehensive Environmental and Social Impact Assessment (ESIA) with associated Environmental and Social Management Plan (ESMP) is currently being undertaken and developed to International Finance Corporation (IFC) standards. The ESIA is being prepared to obtain an Environmental Clearance Certificate (ECC) for the project from Namibian authorities and to supplement a NI-43-101 technical report providing environmental, social compliance components as well as permitting for the project.

Figure 2: Plan view of updated conceptual site layout for the Haib project

The full scope of studies includes terrestrial biodiversity, aquatic ecology, hydrology (surface water and groundwater), geochemistry, air and noise, archaeology and socio economics. Routine monitoring of surface water quality, groundwater quantity and quality as well as air quality (including dust, NO2, SO2 and PM).

These studies have all been completed, or are underway, to inform the early design phase of the project. Further focussed baseline and impact studies have been scheduled for the second half of 2025.

Following the completion of the Baseline Studies, and subsequent impact assessment in the ESIA, an ESMP will be developed and submitted to the Ministry of Environment, Forestry and Tourism (MEFT) for review towards the end of 2025. No fatal flaws have been found in the assessments to date. Comparable environmental permitting processes in Namibia are typically approved within 12-18 months.

Studies Schedule and Timelines

The following main activities and target dates for completion are planned over the next 12 months:

- Completion of pre-concentration (sorting and dense medium separation) tests by end August 2025.

- Publication of a PEA technical report during Q3 2025.

- Completion and evaluation of all column leach (heap leach) tests by end April 2026.

- Mineral resource estimate update during H1 2026

- Publication of updated and enhanced technical report (PEA or PFS) during H1 2026

Qualified Person

Mr. Dean Richards Pr.Sci.Nat., MGSSA – BSc. (Hons) Geology is the Qualified Person for the Haib Copper Project and has reviewed and approved the scientific and technical information in this news release and is a registered Professional Natural Scientist with the South African Council for Natural Scientific Professions (Pr. Sci. Nat. No. 400190/08). Mr. Richards is independent of the Company and its mineral properties and is a Qualified Person for the purposes of National Instrument 43-101.

About Koryx Copper Inc.

Koryx Copper Inc. is a Canadian copper development Company focused on advancing the 100% owned Haib Copper Project in Namibia whilst also progressing its two copper exploration licenses on the Zambian copper belt. Haib is a large, advanced (PEA-stage) copper/molybdenum porphyry deposit in southern Namibia with a long history of exploration and project development by multiple operators. More than 80,000m of drilling has been conducted at Haib since the 1970’s with significant exploration programs led by companies including Falconbridge (1964), Rio Tinto (1975) and Teck (2014). Extensive metallurgical testing and various technical studies have also been completed at Haib to date.

Additional studies are underway aiming to demonstrate Haib as a future long-life, low-cost, low-risk open pit, sulphide flotation copper project with the potential for additional copper production from heap leaching. Haib has a current mineral resource of 414Mt @ 0.35% Cu for 1,459Mt of contained copper in the Indicated category and 345Mt @ 0.33% Cu for 1136Mt of contained copper in the Inferred category (0.25% Cu cut-off).

Mineralization at Haib is typical of a porphyry copper deposit and it is one of only a few examples of a Paleoproterozoic porphyry copper deposit in the world and one of only two in southern Africa (both in Namibia). Due to its age, the deposit has been subjected to multiple metamorphic and deformation events but still retains many of the classic mineralization and alteration features typical of these deposits. The mineralization is dominantly chalcopyrite with minor bornite and chalcocite present and only minor secondary copper minerals at surface due to the arid environment.

Further details of the Haib Copper Project are available in the corresponding technical report titled, "NI 43-101 Technical Report – August 2024 Mineral Resource Estimate for the Haib Copper Project, Namibia" dated effective August 31, 2024 (the "Technical Report"). The Technical Report and other information is available on the Company's website at https://koryxcopper.com and under the Company's profile on SEDAR+ at www.sedarplus.ca.

More information is available by contacting the Company:

ON BEHALF OF THE BOARD OF DIRECTORS

"Heye Daun", President & CEO

Julia Becker

Corporate Communications

jbecker@koryxcopper.com

+1-604-785-0850

Neither the TSX Venture Exchange nor its Regulation Services Provider (as that term is defined in the policies of the TSX Venture Exchange) accepts responsibility for the adequacy or accuracy of this release.

Cautionary Statement Regarding Forward-Looking Information

This press release contains "forward-looking information" within the meaning of applicable Canadian securities legislation. Forward-looking information includes, without limitation, statements regarding timing for completion of the Company's intended preliminary economic assessment (the "PEA") of its Haib Copper Project and the potential projected or processing design capacity for annual copper concentrate production at its Haib Copper Project and the future or prospects of the Company. Generally, forward-looking information can be identified by the use of forward-looking terminology such as "plans", "expects" or "does not expect ", "is expected ", "budget", "scheduled", "estimates", "forecasts", "intends", "anticipates" or "does not anticipate", or "believes", or variations of such words and phrases or state that certain actions, events or results "may", "could", "would", "might" or "will be taken", "occur" or "be achieved". Forward-looking statements are necessarily based upon a number of assumptions that, while considered reasonable by management, are inherently subject to business, market, and economic risks, uncertainties, and contingencies that may cause actual results, performance, or achievements to be materially different from those expressed or implied by forward-looking statements. Although the Company has attempted to identify important factors that could cause actual results to differ materially from those contained in forward-looking information, other factors may cause results not to be as anticipated, estimated, or intended. There can be no assurance that such information will prove to be accurate, as actual results and future events could differ materially from those anticipated in such statements. Accordingly, readers should not place undue reliance on forward-looking information. Other factors which could materially affect such forward-looking information are described in the risk factors in the Company's most recent annual management discussion and analysis. The Company does not undertake to update any forward-looking information, except in accordance with applicable securities laws.

Photos accompanying this announcement are available at:

https://www.globenewswire.com/NewsRoom/AttachmentNg/51fb9607-26c5-4e58-a040-de7ad31400d3

https://www.globenewswire.com/NewsRoom/AttachmentNg/af41a3eb-db96-47a7-b788-5c938b96a67c

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.